Customized Metal Parts Stainless Steel Aluminum Turning Cutting Milling Precision Rapid Prototype Machining Service CNC Parts

$ 0.90

$ 0

Key attributes

Industry-specific attributes

CNC Machining or Not

Cnc Machining

Material Capabilities

Aluminum, Brass, Bronze, Copper, Stainless Steel, Steel Alloys, Hardened Metals, Precious Metals, Plastics

Other attributes

Place of Origin

Guangdong, China

Type

Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not

Micro Machining

Model Number

xlf-3041

Brand Name

XLF

Material

Brass/Aluminium/Stainless Steel/Plastic/Titanium/Plastic/ Alloy

Process

Drilling/Bending/Milling/Turning/laser machining

Finish

Anodize/Powder Coating/Sand blasting ect

Certification

ISO9001&ISO14001

Service

Customized OEM ODM CNC Machining

Tolerance

0.001mm~0.005mm

Surface treatment

Painting\Powder Coating\Plating\Polishing

Drawing Format

2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Keyword

Cnc Machining Parts Cnc Machining Service

Quality Control

100% Inspection Berore Shipment

Packaging and delivery

Selling Units:

Single item

Single package size:

4X6X7 cm

Single gross weight:

3.000 k

Product descriptions from the supplier

Warning/DisclaimerThis product has acquired the relevant product qualification(s)/license(s) of certain applicable country/countries.View more

Video Description

Our company specializes in providing customers with comprehensive solutions for non-standard hardware and plastic products, and is a one-stop service expert. From the processing of raw materials to the assembly of finished products, we are committed to meeting the various needs of our customers through efficient production processes and strict quality control.

Our company specializes in providing customers with comprehensive solutions for non-standard hardware and plastic products, and is a one-stop service expert. From the processing of raw materials to the assembly of finished products, we are committed to meeting the various needs of our customers through efficient production processes and strict quality control.

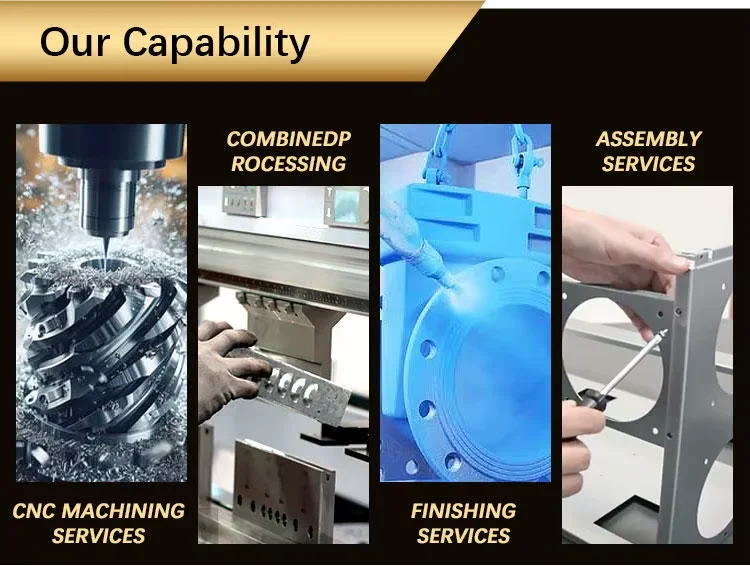

Processing | CNC Machining Services: CNC Milling, CNC Turning, Laser Cutting,drilling ,Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM) 3-axis-4-axis-5-axis Machining, Comprehensive Processing Services: Sheet Metal fabrication, Stamping, Die Casting, 3D Printing, Injection Molding Rapid Prototype,Moulds etc,Multistep Machining |

Assembly Services | Fastening & Splicing, Component Assembly, Full Assembly, Packaging & Labeling |

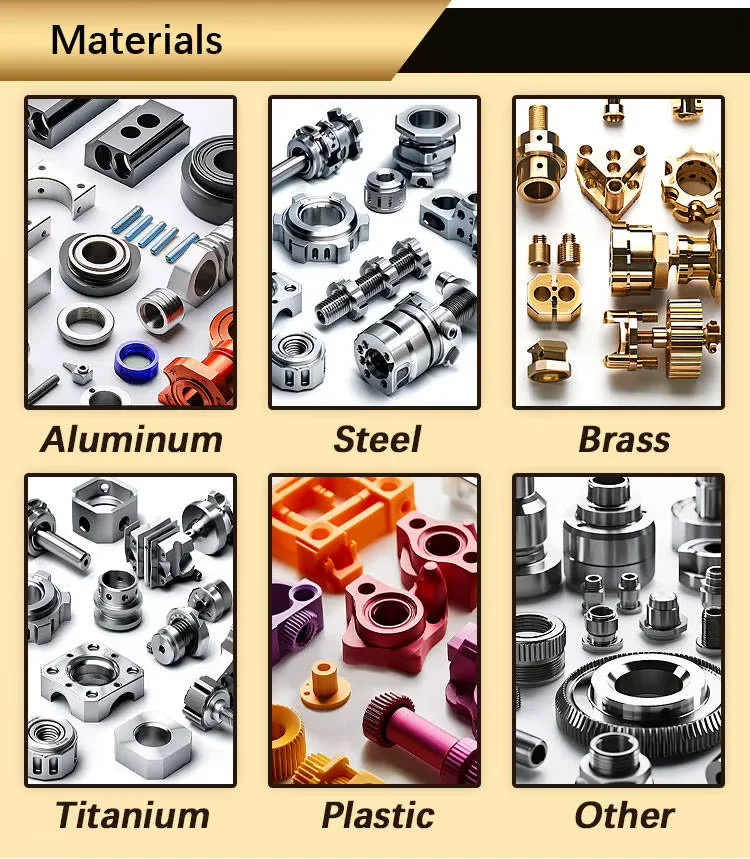

The materials we can process are• Material | Aluminum, Stainless Steel, Titanium ,Barss,Copper,Plastic,Alloy Custom material |

Precision Tolerance | ±0.001mm~±0.005mm |

Surface Roughness | Min Ra 0.1~3.2 |

Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, sandblasting ,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

Production volume | Low to Medium Volume, Prototype, and Batch Production |

Processing Method | Custom According to Provided CAD Drawings |

Lead Time | Short lead Time, Typically 1-4 Weeks |

Quality Control | Strict Quality Assurance and Inspection Processes |

Packaging | Secure Packaging to Prevent Damage During Transit |

Certificate | ISO9001,AS9100D,ISO45001,ISO14001,ROSH,CE etc. |

1-Piece minimum order | Ability to Provide Samples Before Mass Production |

Customized Precision Parts | We Look Forward to Receiving Your Customized Requirements and Establishing a Fruitful Partnership. |

Aluminum: lightweight, strong, and corrosion-resistant and is used in aerospace, automotive, and electronics. Grades: 6061, 7075, 5052, 2024.

Steel: strong, durable and versatile, making it ideal for construction, machinery and automobiles. Steel grades 304, 316, 1018, 4140.

Brass: corrosion-resistant and conductive and is used in electronics, plumbing and decorative parts. Grades: H59, H62, C360, C272: H59, H62, C360, C272.

Plastics: lightweight, insulating, and durable, making them ideal for use in electronics, medical, and consumer products. Types POM, ABS, Nylon, Teflon.

Aluminum: lightweight, strong, and corrosion-resistant and is used in aerospace, automotive, and electronics. Grades: 6061, 7075, 5052, 2024.

Steel: strong, durable and versatile, making it ideal for construction, machinery and automobiles. Steel grades 304, 316, 1018, 4140.

Brass: corrosion-resistant and conductive and is used in electronics, plumbing and decorative parts. Grades: H59, H62, C360, C272: H59, H62, C360, C272.

Plastics: lightweight, insulating, and durable, making them ideal for use in electronics, medical, and consumer products. Types POM, ABS, Nylon, Teflon.

Surface Treatment | Description | Materials | Purpose |

Machining | Smooth surface via CNC cutting | Metals, Plastics | Base finish, precision parts |

Sandblasting | Matte or textured finish by particle blasting | Aluminum, Steel, Brass | Pre-treatment, decorative |

Anodizing | Hard coating with corrosion resistance | Aluminum | Anti-corrosion, decorative |

Hardening | Increases surface hardness | Steel | Wear resistance, durability |

Electroplating | Metal coating for protection or conductivity | Steel, Aluminum, Brass | Anti-corrosion, enhanced look |

Polishing | Smooth or mirror-like finish | Aluminum, Steel, Brass | Aesthetic, reduces friction |

Brushing | Painted surface for protection | Metals, Plastics | Anti-rust, decorative coating |

Powder Coating | Durable, uniform protective layer | Aluminum, Steel, Brass | Anti-wear, colorful finishes |

Chemical Oxidation | Oxide layer for corrosion resistance | Steel, Aluminum | Industrial or decorative use |

Galvanizing | Zinc coating for rust protection | Steel | Outdoor or structural use |

A Note about Our Customization | |||

Features | CNC Milling Parts | CNC Turning Parts | |

Maximum Part Size | 236" x 118" x 24" | 62" Length x 32" Diameter | |

Minimum Feature Size | 0.020″ (0.50 mm) | 0.020″ (0.50 mm) | |

Estimated Delivery Time | 3-7 working days | 3-7 working days | |

Standard Tolerance | ISO 2768 MK | ISO 2768 MK | |

Precision Tolerance | ±0.0002" (±0.005mm) | ±0.0002" (±0.005mm) | |

Threads and Threaded Holes | Standard threads and holes available, also customizable. | Standard threads and holes available, also customizable. | |

Edge Conditions | Deburring by default. | Deburring by default. | |

Surface Smooth | Ra 0.4 - 1.6μm | Ra 0.4 - 1.6μm | |